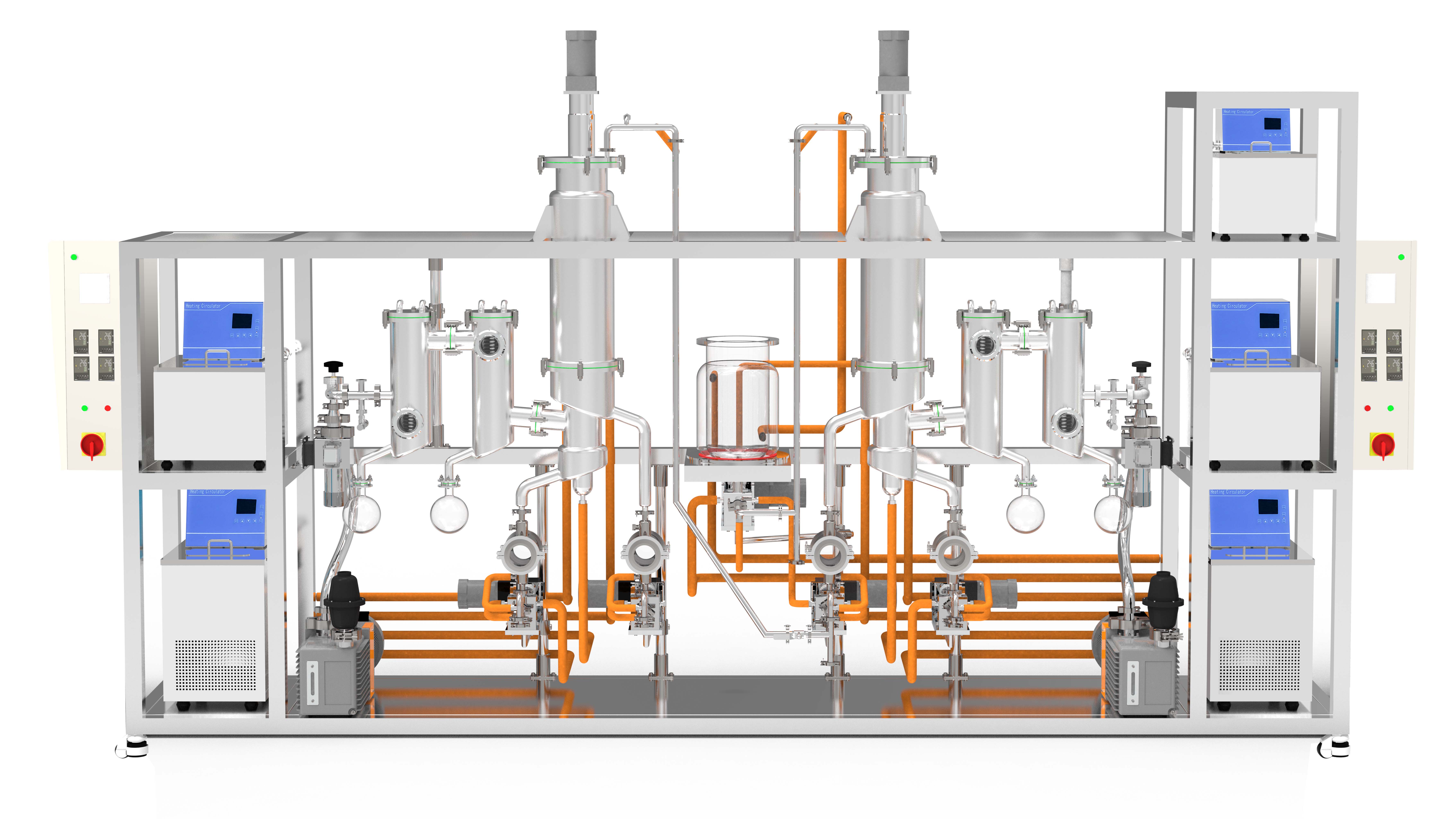

Stainless Steel Dual Stage Wiped Film Distillation Unit

Most traditional wiped film molecular distillation require each distillation pass to be performed in a single, separate cycle. Not only does this create a bottleneck in the production process, it also leaves the risks of contamination and product waste between transfers in your lab. For any serious distillate producer, this should not be an acceptable standard.

With two separate thin film evaporator stills capable of a clean, capable of eliminating waste and contamination, doubling output and halving labor costs compared to standard single stage systems.

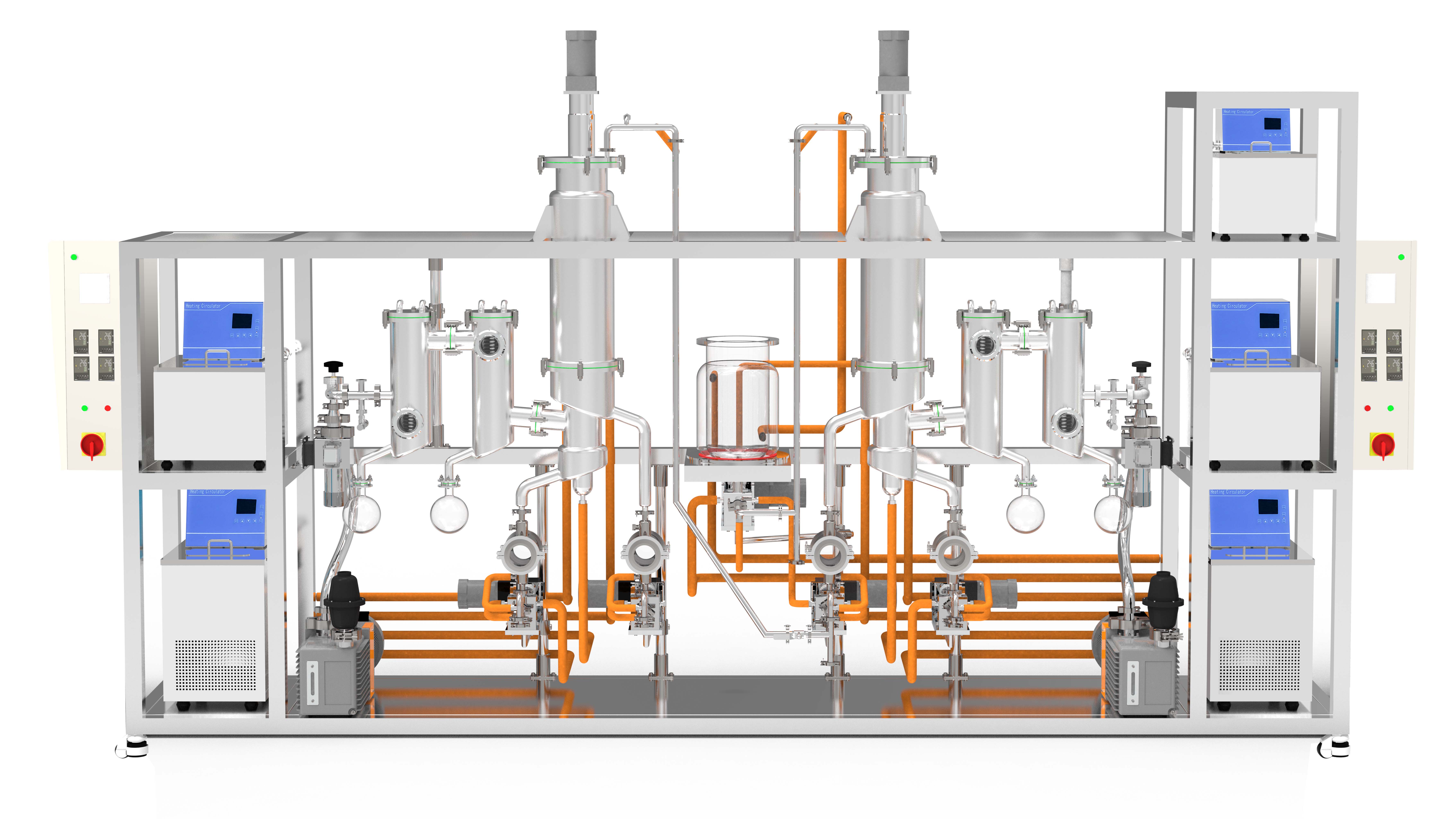

Stainless Steel Dual Stage Wiped Film Distillation Unit

Most traditional wiped film molecular distillation require each distillation pass to be performed in a single, separate cycle. Not only does this create a bottleneck in the production process, it also leaves the risks of contamination and product waste between transfers in your lab. For any serious distillate producer, this should not be an acceptable standard.

With two separate thin film evaporator stills capable of a clean, capable of eliminating waste and contamination, doubling output and halving labor costs compared to standard single stage systems.

- Driving motor with magnetic coupling sealing ensures high vacuum level

- Continuous feeding and discharging under vacuum state are realized by gear pump

- External two stage condensers with chiller for better protection for the Vacuum pump

- recise temperature control and fully jacketed system ensures high quality and productivity

- Stainless steel with faster heat conduction is adopted, and 316L stainless steel is used in contact with materials

- A variety of configurations are available to meet the customer’s budget

Model |

QYMD-0.1SS |

QYMD-0.15SS |

QYMD-0.25SS |

QYMD-0.35SS |

QYMD--0.5SS |

Effective evaporation area(m2) |

0.1 |

0.15 |

0.25 |

0.35 |

0.5 |

Internal Condensation Area(m2) |

0.15 |

0.2 |

0.4 |

0.5 |

0.65 |

Feed rate(L/h) |

2-10 |

5-15 |

10-25 |

15-30 |

20-60 |

Feed tank volume(L) |

10 |

15 |

20 |

20 |

50 |

Speed(r/min) |

0~300 |

||||

Material |

Stainless Steel 304 external, 316 internal |

||||

Motor film scraping system |

roller wiper available system with speed adjustable drive system and magnetic coupling |

||||

Material of wiper rollers |

PTFE (max operating temperature 300°C) |

||||

Volume of light component collect flask |

The gear pump discharges continuously and is equipped with an observable window |

||||

Volume of heavy component collect flask |

The gear pump discharges continuously and is equipped with an observable window |

||||

Motor power(W) |

60 |

120 |

120 |

200 |

200 |

Work temperature |

Evaporator max operating temperature 250°C(Optional 300℃) Condenser operating temperature range -20°C to 100°C(Optional) |

||||

Voltage(V) |

220V 50 60HZ |

||||