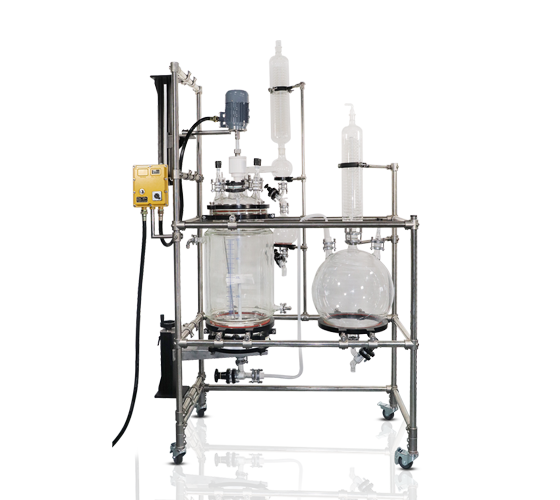

Extraction module

Solvent ethanol extraction is often the first step in refinement in order to recover cannabis essential oils containing precious THC, CBD and therpene compounds. The aim of extraction is to produce oils that are free from particulates and that contain the medicinally-relevant compounds (cannabinoids) in a higher concentration than raw cannabis and hemp. In the ethanol extraction process the choice of process parameters will vary depending on starting materials (quality and size) desired end product and other considerations. Ethanol extraction is often used due to its availability, efficiency and relatively safe process.

Filtration module

Single filter bag is for some coarse filtration and pre-filtration process. Lenticular filter is a new type of stacks filter, can be used in place of diatomite filter, for tiny impurities in varied kinds of liquid filtration, clarification, and purification.The two filters can be used together to filter and remove impurities of the crude oil extracted from Biomass. This essential step removes plant waxes and particulates. It is critical to producing a translucent final product which is convenient for the next step of purification by evaporation and distillation.

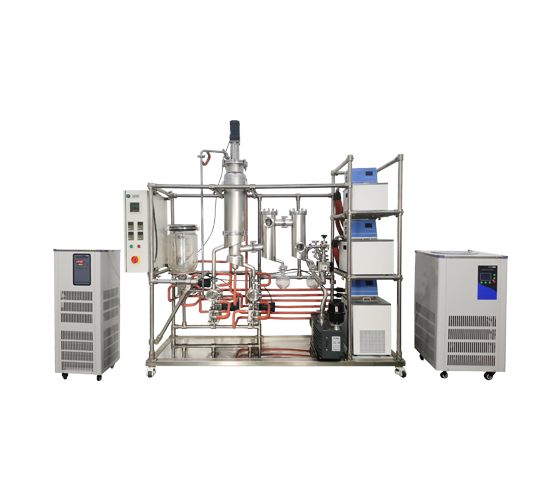

Evaporation module

The feed liquid for the falling film evaporator is added from the top of the heating tube. Under the action of gravity, the solution flows downward in a membrane form along the inner wall of the pipe and is evaporated and concentrated. Vapor-liquid mixture enters the separation chamber from the bottom of the heating pipe. After gas-liquid separation, the liquid is discharged from the bottom of the separator.

Solvent handling is better than rotary evaporator. Crude oil mixed solvent after extraction is desolved in falling film evaporator and then crude oil is obtained.

Distillation module

Molecular distillation is a special liquid-liquid separation equipment. Unlike traditional distillation, it relies on the boiling point difference separation principle, but on the difference of the average free path of different substances. When the liquid mixture flows along the inner wall of the main evaporator and is heated, light and heavy molecules will escape from the liquid level and enter the gas phase. Due to the different free paths of light and heavy molecules, the molecules of different substances move different distances after escaping from the liquid level. After passing through the built-in condensate pipe of the main evaporator, the light molecules reach the condensate pipe and are discharged, while the heavy molecules cannot reach the condensate pipe and are discharged along the mixed liquid, So as to achieve the purpose of material separation.

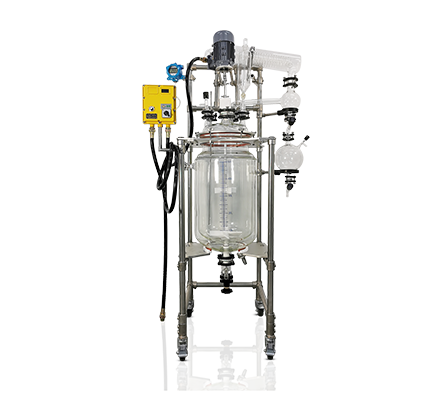

Crystallization Module

If need CBD isolated , crystallization is suitable. The solvent is pentane. The crystallization process is realized through temperature control, so as to achieve solid-liquid separation and get CBD isolated. Our nutsche filter reactor is filled with heating and cooling medium through the jacket and stirred at a constant speed to precipitate crystals. Materials can be glass and stainless steel.

Drying module

Vacuum drying oven is a box type drying equipment that dries dry materials under negative pressure. It uses a vacuum pump to pump air and humidity, so as to form a vacuum state in the working room, reduce the boiling point of water and speed up the drying speed. Used for powder drying, defoaming, dehydration, hardening and drying in the production of electronic products. It is widely used in electronic chemistry, agricultural scientific research, environmental protection and other research fields.