Product Description

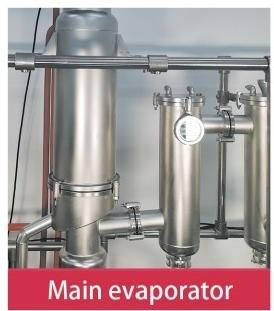

Molecular distillation is a special liquid-liquid separation equipment. Unlike traditional distillation, it relies on the boiling point difference separation principle, but on the difference of the average free path of different substances. When the liquid mixture flows along the inner wall of the main evaporator and is heated, light and heavy molecules will escape from the liquid level and enter the gas phase. Due to the different free paths of light and heavy molecules, the molecules of different substances move different distances after escaping from the liquid level. After passing through the built-in condensate pipe of the main evaporator, the light molecules reach the condensate pipe and are discharged, while the heavy molecules cannot reach the condensate pipe and are discharged along the mixed liquid, so as to achieve the purpose of material separation.

Work Program

The materials are transported from the feed tank to the jacketed main evaporator. The main evaporator is continuously heated. The built-in scraper evenly scrapes the materials into a layer of flowing liquid film for instant evaporation. The light component materials begin to vaporize and adsorb on the built-in condensing coil, flow into the receiving bottle along the outer wall of the condensing pipe, and the heavy component materials flow into the receiving bottle along the inner wall of the main evaporator.

Application

-

Extraction ofdeep sea fish oil

Extraction ofdeep sea fish oil -

Extraction of CBD oil

Extraction of CBD oil -

Pharmaceuticals

Pharmaceuticals -

Concentration of plant essential oil

Concentration of plant essential oil -

Separation of vitamin/ nutritional essential oil

Separation of vitamin/ nutritional essential oil -

Chemical Research

Chemical Research

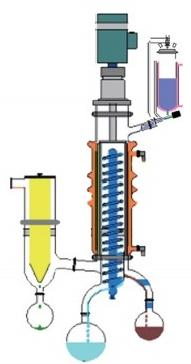

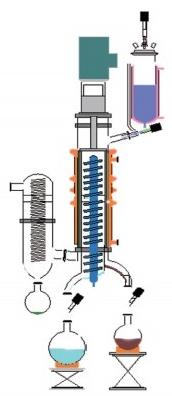

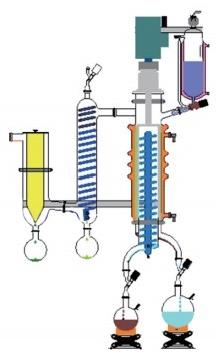

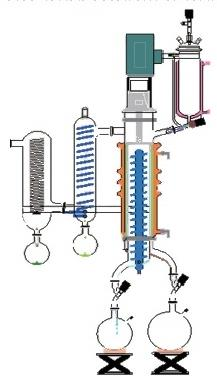

Short path glass molecular distillation

Optional model

-

Model—A

One extra cold trap

-

Model—B

One extra condenser with chiller

-

Model—C

One extra condenser with chiller and cold trap

-

Model—D

Two extra condenser with chiller

Advantage

- High evaporation efficiency, process time short

- The residence time is short, and the thermal sensitive material is not easy to deteriorate and carbonize

- The connection port adopts ball milling port design to ensure that molecular distillation is always in high vacuum

- Glass material, easy to observe process program

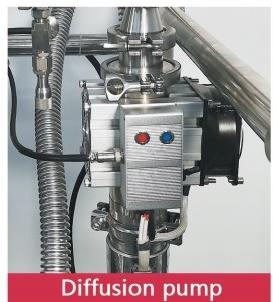

- Can reach 0.1Pa with diffusion pump and high efficiency distillation

- The main evaporator adopts jacket design, with high heating efficiency and strong thermal insulation performance

- Can continuous feeding and discharging

Attention

- Fill the cold trap with liquid nitrogen for freezing in advance

- Equipment heating with oil, high temperature, do not touch with hand, avoid scalding

- Work temperature from -80℃ to 250℃ (300℃ need customized)

- Check cooling water valve is open normal or not before use

Technical parameter

| Model | QYMD-60 | QYMD-80 | QYMD-100 | QYMD-150 | QYMD-200 | QYMD-230 |

|---|---|---|---|---|---|---|

| Main evaporator diameter (mm) | 60 | 80 | 100 | 150 | 200 | 230 |

| Effective evaporation area (m²) | 0.06 | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 |

| Feed rate (Kg/h) | 0.5-3.0 | 1.0-5.0 | 2.0-8.0 | 3.0-15.0 | 5.0-20.0 | 8.0-30.0 |

| Feed tank volume (L) | 1 | 1 | 2 | 2 | 5 | 5 |

| Speed (r/min) | 450 | 450 | 450 | 450 | 300 | 300 |

| Volume of light component collect flask | 1L | 1L | 2L | 3L | 5L | 5L |

| Volume of heavy component collect flask | 1L | 1L | 2L | 3L | 5L | 5L |

| Motor power (W) | 90 | 120 | 120 | 120 | 200 | 200 |

| Work temperature | -90℃~220℃ | -90℃~220℃ | -90℃~220℃ | -90℃~220℃ | -90℃~220℃ | -90℃~220℃ |

| Voltage (V) | 220V/50Hz can be customized | 220V/50Hz can be customized | 220V/50Hz can be customized | 220V/50Hz can be customized | 220V/50Hz can be customized | 220V/50Hz can be customized |

Stainless steel molecular distillation

Parts details

-

Can show vacuum pressure temperature and speed

-

SUS material,better therma conductivity,good evaporation effect and not easy damage

-

Jacket can through fluid to warm material in advance

-

Windows design,easy to observe material process program,gas condenses more thoroughly

-

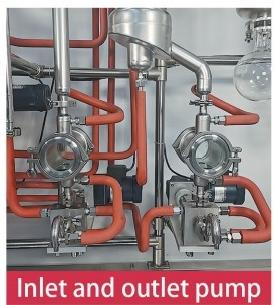

Continuous feeding and discharging to improve work efficiency

-

Improve vacuum degree to 0.1Pa

Advantage

- For the separation of high boiling point, heat sensitive, and easily oxidized materials, stainless steel molecular distillation provides a good separation method

- Stainless steel molecular distillation operates at a temperature far below the boiling point of the material, and the material residence time is short

- The inner wall of the main evaporator is smooth and clean and is not easy to stick and scale

Attention

- After starting feeding, adjust the speed of the mixing motor according to the feeding speed and material viscosity

- Before start-up, the equipment must reach the vacuum state to avoid reducing the evaporation efficiency

- The system cleaning is carried out under normal pressure. After the experiment, the lightweight is separated, the receiving flask is installed, and the vacuum probe is removed to avoid corrosion

Technical parameter

| Model | QYMD-0.1SS | QYMD-0.155S | QYMD-0.25SS | QYMD-0.355S | QYMD-0.5SS | QYMD-15S | QYMD-1.55S | QYMD-2SS | QYMD-3SS | QYMD-5SS |

|---|---|---|---|---|---|---|---|---|---|---|

| Condenser area (m²) | 0.17 | 0.3 | 0.4 | 0.7 | 1.7 | 2.7 | 3.5 | 4.9 | 6.5 | 8 |

| Effective evaporation area (m²) | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 | 1.5 | 3 | |||

| Feeding rate (L/H) | 5~12 | 6~15 | 10~25 | 15~30 | 20~60 | 50~120 | 60~180 | 100~200 | 100~300 | 200~500 |

| RPM (r/min) | 30~350 | 30~350 | 30~350 | 30~350 | 30~350 | 30~350 | 30~350 | 30~350 | 30~350 | 30~350 |

| Stainless steel material | 316/304 | 316/304 | 316/304 | 316/304 | 316/304 | 316/304 | 316/304 | 316/304 | 316/304 | 316/304 |

| Feeding method | Gear pump automatic continuous feeding | Gear pump automatic continuous feeding | Gear pump automatic continuous feeding | Gear pump automatic continuous feeding | Gear pump automatic continuous feeding | Gear pump automatic continuous feeding | Gear pump automatic continuous feeding | Gear pump automatic continuous feeding | Gear pump automatic continuous feeding | Gear pump automatic continuous feeding |

| Discharge method | Gear pump automatic continuous discharge | Gear pump automatic continuous discharge | Gear pump automatic continuous discharge | Gear pump automatic continuous discharge | Gear pump automatic continuous discharge | Gear pump automatic continuous discharge | Gear pump automatic continuous discharge | Gear pump automatic continuous discharge | Gear pump automatic continuous discharge | Gear pump automatic continuous discharge |

| Work temperature (℃) | Within 350℃ | Within 350℃ | Within 350℃ | Within 350℃ | Within 350℃ | Within 350℃ | Within 350℃ | Within 350℃ | Within 350℃ | Within 350℃ |

| Voltage (V) | 200V/50Hz can be customized | 200V/50Hz can be customized | 200V/50Hz can be customized | 200V/50Hz can be customized | 200V/50Hz can be customized | 200V/50Hz can be customized | 200V/50Hz can be customized | 200V/50Hz can be customized | 200V/50Hz can be customized | 200V/50Hz can be customized |

wiped film distillation

Work program

- After the material enters the evaporator,it is stirred by the scraper to form a film quickly.The heat source heat is heated and exchanged with the material liquid through the cylinder wall.The liquid film boils and liquefies,enters the condenser,condenses into liquid and is discharged,and the concentrated liquid is discharged from the bottom discharge port.At present,foreign film evaporators have been developed in the direction of large-scale,serialization and generalization,and have been widely used in disillation,separation,concentration,extraction,deodorization,degassing,reaction and other processes.

Attention

- High evaporation efficiency and short material residence time

- High borosilicate glass material,corrosion resistance,high temperature resistance,high visibility

- The magnetic seal ensures the high altitude of the equipment

- It can easily handle materials with high boiling point and high viscosity

Technical parameter

| Model | QYBM-60 | QYBM-80 | QYBM-100 | QYBM-150 | QYBM-200 | QYBM-230 |

|---|---|---|---|---|---|---|

| Main evaporator diameter (mm) | 60 | 80 | 100 | 150 | 200 | 230 |

| Effective evaporation area (m²) | 0.06 | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 |

| Feed rate (Kg/h) | 0.5-3.0 | 1.0-5.0 | 2.0-8.0 | 3.0-15.0 | 5.0-20.0 | 8.0-30.0 |

| Feed tank volume (L) | ||||||

| Speed (r/min) | 450 | 450 | 450 | 450 | 300 | 300 |

| Volume of heavy component collect flask | 1L | 1L | 2L | 3L | 5L | 5L |

| Motor power (W) | 90 | 120 | 120 | 120 | 200 | 200 |

| Work temperature | -90℃~220℃ | -90℃~220℃ | -90℃~220℃ | -90℃~220℃ | -90℃~220℃ | -90℃~220℃ |

| Voltage (V) | 220V/50Hz can be customized | 220V/50Hz can be customized | 220V/50Hz can be customized | 220V/50Hz can be customized | 220V/50Hz can be customized | 220V/50Hz can be customized |

practical cases