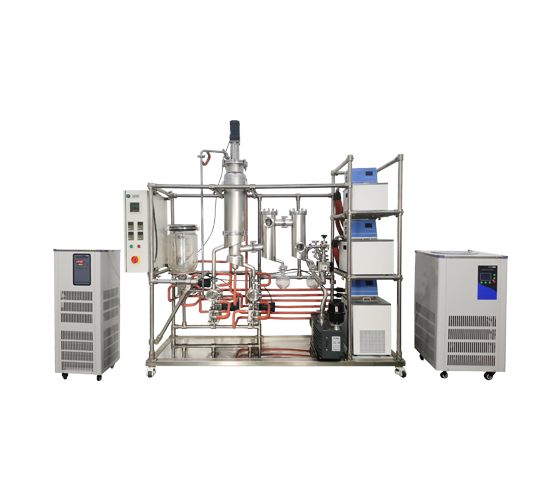

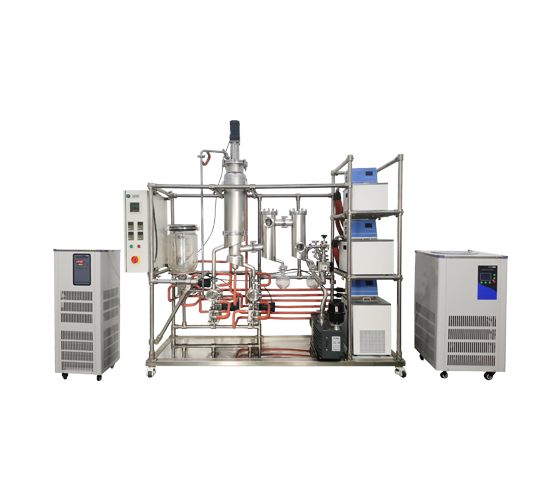

Stainless steel wiped film molecular distillation system-For lab distillation volume

- Feed rate from 1L to 50L per hour

- Driving motor with magnetic coupling sealing ensures high vacuum level

- Continuous feeding and discharging under vacuum state are realized by gear pump

- External two stage condensers with chiller for better protection for the Vacuum pump

- Precise temperature control and fully jacketed system ensures high quality and productivity

- Stainless steel with faster heat conduction is adopted, and 316L stainless steel is used in contact with materials

Wiped film stainless steel molecular distillation system

Molecular distillation is a special liquid-liquid separation equipment. Unlike traditional distillation, it relies on the boiling point difference separation principle, but on the difference of the average free path of different substances. When the liquid mixture flows along the inner wall of the main evaporator and is heated, light and heavy molecules will escape from the liquid level and enter the gas phase. Due to the different free paths of light and heavy molecules, the molecules of different substances move different distances after escaping from the liquid level. After passing through the built-in condensate pipe of the main evaporator, the light molecules reach the condensate pipe and are discharged, while the heavy molecules cannot reach the condensate pipe and are discharged along the mixed liquid, So as to achieve the purpose of material separation.

- Stainless steel wiped film molecular distillation system-For lab distillation volume

- Feed rate from 1L to 50L per hour

- Driving motor with magnetic coupling sealing ensures high vacuum level

- Continuous feeding and discharging under vacuum state are realized by gear pump

- External two stage condensers with chiller for better protection for the Vacuum pump

- Precise temperature control and fully jacketed system ensures high quality and productivity

- Stainless steel with faster heat conduction is adopted, and 316L stainless steel is used in contact with materials

- A variety of configurations are available to meet the customer’s budget

Model |

QYMD-0.1SS |

QYMD-0.15SS |

QYMD-0.25SS |

QYMD-0.35SS |

QYMD--0.5SS |

Effective evaporation area(m2) |

0.1 |

0.15 |

0.25 |

0.35 |

0.5 |

Internal Condensation Area(m2) |

0.15 |

0.2 |

0.4 |

0.5 |

0.65 |

Feed rate(L/h) |

2-10 |

5-15 |

10-25 |

15-30 |

20-60 |

Feed tank volume(L) |

10 |

15 |

20 |

20 |

50 |

Speed(r/min) |

0~300 |

||||

Material |

Stainless Steel 304 external, 316 internal |

||||

Motor film scraping system |

roller wiper available system with speed adjustable drive system and magnetic coupling |

||||

Material of wiper rollers |

PTFE (max operating temperature 300°C) |

||||

Volume of light component collect flask |

The gear pump discharges continuously and is equipped with an observable window |

||||

Volume of heavy component collect flask |

The gear pump discharges continuously and is equipped with an observable window |

||||

Motor power(W) |

60 |

120 |

120 |

200 |

200 |

Work temperature |

Evaporator max operating temperature 250°C(Optional 300℃) Condenser operating temperature range -20°C to 100°C(Optional) |

||||

Voltage(V) |

220V 50 60HZ |

||||