ZYJ-2L Glass Distillation Tower

Reading volume: 0

Collection: 0

Share links

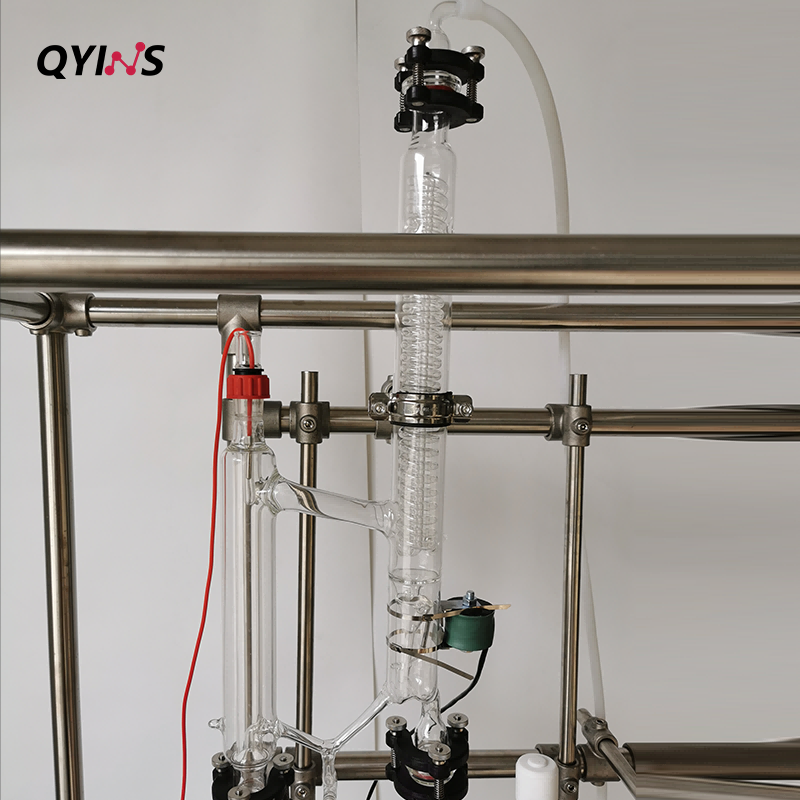

- Multiple trays or packing layers are installed inside the tower to increase the gas-liquid contact area and improve separation efficiency

- The tray can be of bubble cover plate, sieve plate and other types, while the packing can be bulk packing or regular packing

- There are inlet and outlet ports on the tower body for the input of the mixture and the output of each component after separation

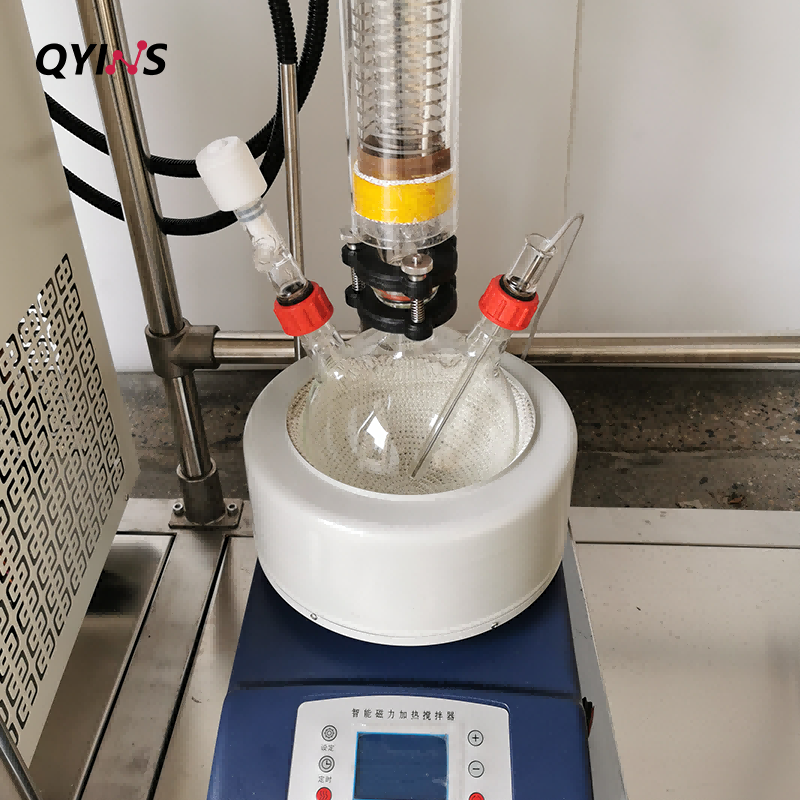

- Heating Method: Steam Heating / Electric Heating (optional)

Multiple trays or packing layers are installed inside the tower to increase the gas-liquid contact area and improve separation efficiency

The tray can be of bubble cover plate, sieve plate and other types, while the packing can be bulk packing or regular packing

There are inlet and outlet ports on the tower body for the input of the mixture and the output of each component after separation

Heating Method: Steam Heating / Electric Heating (optional)

The working principle of the fractionation tower is based on the difference in boiling points of each component in the mixture. When the mixture is heated to a certain temperature, the components with lower boiling points begin to vaporize, while the components with higher boiling points remain liquid. These vaporized components then rise within the tower and undergo heat exchange upon contact with the descending condensate, resulting in condensation into a liquid state.